Automation engineering

will transform your business

CR Automation is transforming the way industrial businesses operate. We enable industry to become cleaner, safer, sustainable and energy efficient, while improving productivity.

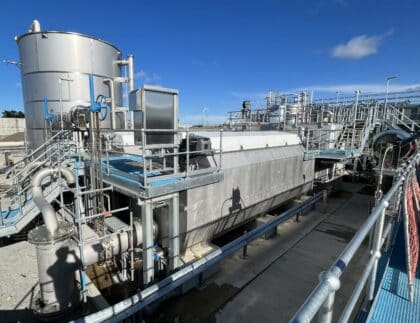

From discrete machines through to large green field turnkey industrial installations, our clients enjoy cost-effective, fit for purpose, future-proofed systems, delivered on time, to specification and budget.

Contact us to discover how automation solutions can transform your business.

Our Core Business Areas

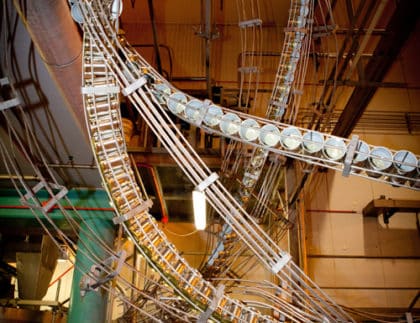

CR Automation has years of expertise in post harvest automation. Our clients have easy to use processing equipment, that enables them to access higher value markets...

With the increased need to have safer working environments and to comply with workplace health and safety, machine safety is paramount...

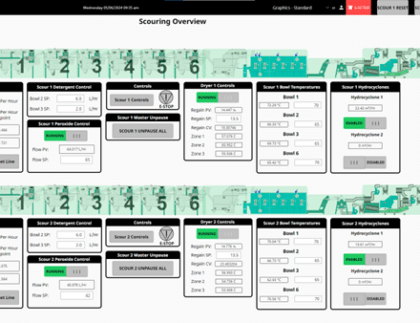

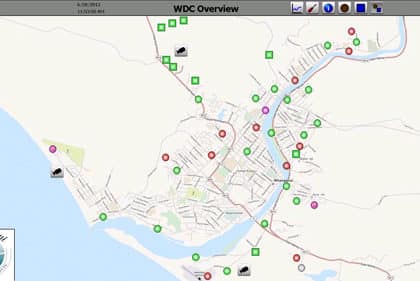

Automation is the key to increased productivity, greater efficiency, improving reliability while reducing costs in your business operations...

Robotics

From heavy lifting to repetitive handling and assembly, robots are changing the face of warehousing and industrial processes...

Our Company

CR Automation, incorporated in 2002, delivers industrial automation solutions to customers throughout New Zealand and internationally. With a highly skilled inhouse team of experienced electrical and mechanical engineers, automation engineers, SCADA experts and metalwork fabrication CR Automation is the ideal partner to successfully deliver your automation solution.

We provide

Servicing

All automation engineering solutions are supported by regular servicing and maintenance. We also support other pre-existing installations to ensure your business continues to operate smoothly.