Nailing a robotics engineering problem

Our Client

Tumu Timbers

Project Scope

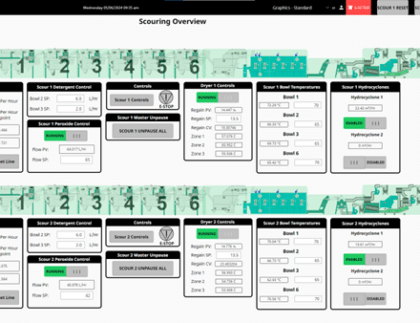

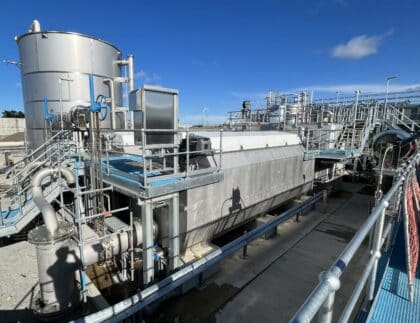

Tumu Timbers had a curious problem that needed a robotics engineering solution. They simply couldn’t find people for the specialised task of manufacturing pallets.

Getting people to assemble pallets by hand required workers with significant body strength to handle timber and a nail gun all day. Not only was this a safety issue, but the consistency of assembly was variable, creating internal quality control issues and costing them money.

The CR Automation Solution

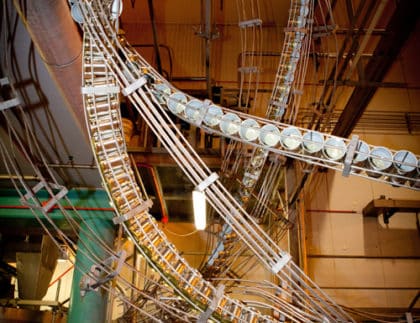

The answer was always going to be a robot, but needless to say, there isn’t an off the shelf solution for such a specialised task. So we designed and built a head for a robot capable of handling three nail guns at once. Using industrial vision, the robot places each nail in the correct spot every time, eliminating inconsistency and human error.

As the robot operates with human workers, we installed safety software with a category three safety rating to control delivery of the nails from the guns. This was a New Zealand first.

The results

It isn’t often we get to say we nailed a job and mean it literally. Not only did Tumu Timbers get a solution that made their pallet assembly a smooth operation, we won the ABB Most Innovative Solution Award for 2019.