Robust and reliable control of water infrastructure

As an essential of life, CR Automation has focused on developing automated, robust and reliable systems to ensure continuity of water services and supply. Our team has designed, installed and maintained systems in New Zealand and overseas. With a high level of automation, the systems we’ve designed and installed require minimal management. They can be monitored from anywhere in the world, with real time critical alerts for rapid support.

Contact us discover how automation engineering can transform your business.

Water Solutions

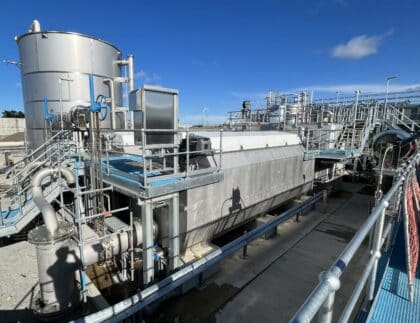

CR Automation have many years experience designing and delivering complete process control systems for water and wastewater plants locally and internationally.

Trade waste pumping stations can be designed for simple and more complex industrial users, ensuring uninterrupted operations and the data needed for local council compliance.

CR Automation have provided complete electrical designs for many water infrastructure facilities both in New Zealand and overseas.

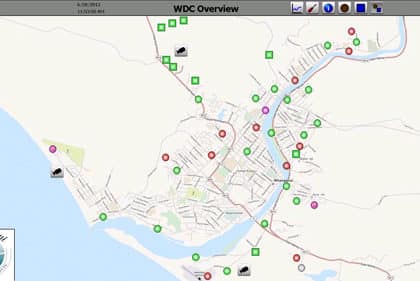

Our systems can be monitored from anywhere in the world, with real time critical alerts sent to control rooms or directly to operators, ensuring information is delivered when its needed.

CR Automation understands critical assets such as water infrastructure needs to be operating 24/7. Our service support with remote site access and on call engineers gives you that piece of mind.

Water servicing and maintenance

We provide water engineering maintenance services for sites we install and pre-existing installations. We can provide a regular schedule of maintenance to ensure ongoing compliance.