Our automation solutions have literally changed the way our clients do business, giving them greater efficiencies, a competitive edge and the ability to access new markets.

This is because automation optimises processes, reducing downtime and waste when you need to be operating at peak output. Many industrial processes can be fully automated, increasing reliability, repeatability and safety within your operation. The net result is a better return on the bottom line.

Contact us discover how automation engineering can transform your business.

Automation Solutions

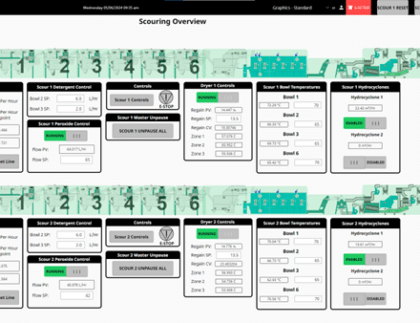

CR Automation have experience implementing complex continuous process controls across many industries.

Both new and existing manufacturing lines can be optimised by automation technologies. Improving throughput, automating quality checks and data analysis are typical goals for our manufacturing clients.

Older installations of control systems present a significant risk to business continuity. CR Automation have the experience to migrate older and obsolete systems over to currently supported hardware & software.

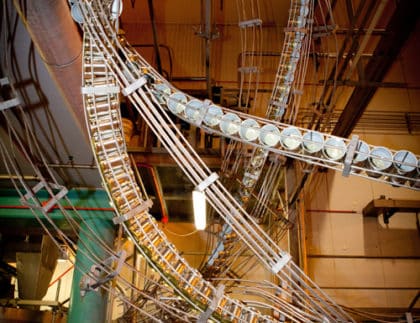

Electrical design for industrial control systems ensures safe, efficient operation of machinery. We specialize in robust control networks and power distribution, prioritizing industry compliance and advanced technology for reliable, efficient systems.

Automation with Robotics

Robotic automation solutions are applicable for a variety of tasks, from heavy lifting to dexterous repetitive work, which are potentially harmful or onerous for people to perform.

Ongoing servicing

and support

More than being an automation solutions provider, we’re also your partner for ongoing servicing and support, ensuring you keep running at peak efficiency. We also service existing installations from other providers.