Robotics and automation that stacks up

Our Client

Kraft Heinz

Project Scope

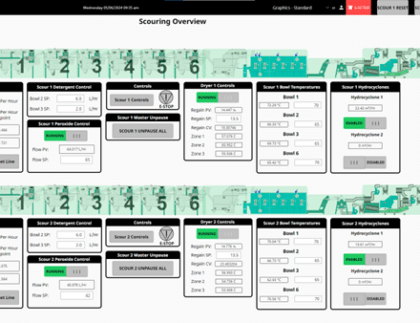

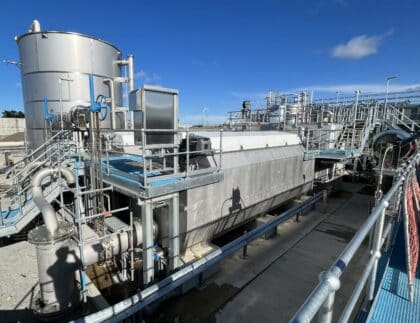

Kraft Heinz needed a robotics and automation solution that could keep up with the speed cans come out of the hydrostatic cooker, getting cans onto pallets, ready for labelling. They wanted to remove legacy bright stack machinery and gain more assurance around stack patterns for canned goods. The current system was inconsistent, had lots of downtime and a high can size changeover time.

The CR Automation Solution

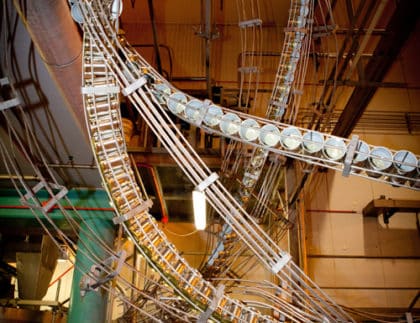

Adding complexity to the job, we had a tight footprint on which to build a solution. It required innovative design. Secondly, we had the challenge to create stable patterns of cans, offsetting the cans, with dynamic can control to maximise storage on a palate. The old kit was time intensive, so we also had to factor in speed, reliability and safety.

The results

The robotic, automated solution we designed not only replaced several old machines, it did the job better. Kraft Heinz now see consistent can stacking, with no compromised palates or gaps, protecting the integrity of the palates. We delivered a high speed can palletising solution, saving time with fast changeover for different can sizes. With innovative design, we configured a machine to perform a complex process on a small footprint, without loss of speed.