Winery automation that's maturing like a great vintage

Our Client

Hawk Packaging

Project Scope

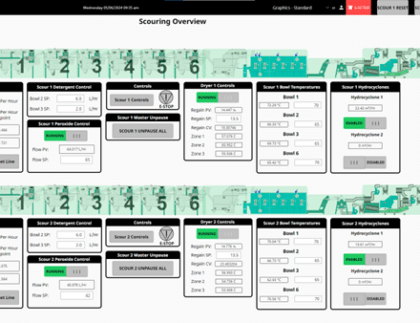

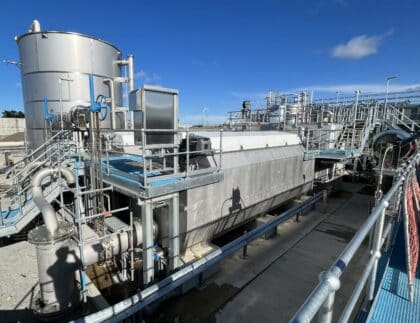

Hawk Packaging take kerbside recycling from across the Lower North Island and convert it into packaging for apple trays.

Their new greenfield site required us to design a factory automation solution for complex industrial process with different machines, liquids, chemicals and flow rates. Each step in the process is critical to the next. Hawk also needed a sustainable operation, not just recycling waste, but all water used in the manufacturing processes.

The CR Automation Solution

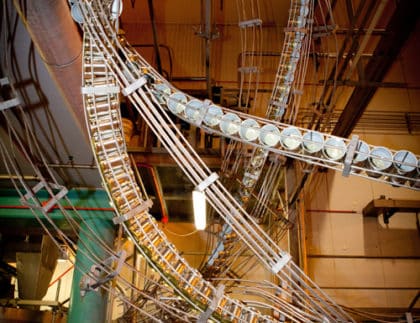

CR Automation provided electrical design, electrical and IT sub contractor management, supply of instrumentation and control equipment, software development, commissioning and support.

The control system comprises of a wide range of technologies including: Process control, burner control, materials handling, robotic palletising, historical data logging, product weight sampling, pallet labelling, interface to Microsoft Dynamics NAV ERP system and custom reports from SQL Server.

The control system integrates the entire factory with a simple SCADA interface built with Wonderware's ArchestrA System Platform on virtualised servers. The operator interfaces utilise large touch screen displays, and iPads for portability and remote access.

The results

Hawk have a state of the art manufacturing facility where the degree of automation is so sophisticated, the 24/7 plant can be operated by three people. The SCADA can be accessed by management remotely from their iPads and production reports are delivered automatically.