Case Study – Complete site rebuild for WoolWorks Awatoto

Our Client - Woolworks

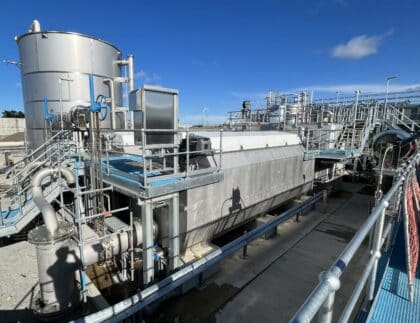

WoolWorks is New Zealand’s only wool scouring service provider, which processes raw wool through water and presses it into bales ready for export. During the scouring process the wool grease is also extracted and processed.

Project Scope

WoolWorks’ existing Awatoto site required a substantial rebuild after flood damage caused by Cyclone Gabrielle. We were asked to implement a new control system for their machinery based on no documentation and limited, outdated software, which ran on legacy equipment. The machines on site were also previously operated as stand-alone and WoolWorks wanted to integrate all machines in their scouring process and control them using a new sitewide SCADA system.

The CR Automation Solution

CR Automation provided a complete site electrical redesign as well as network and control architecture design, supply of instrumentation and control equipment, software development, commissioning, and 24/7 support.

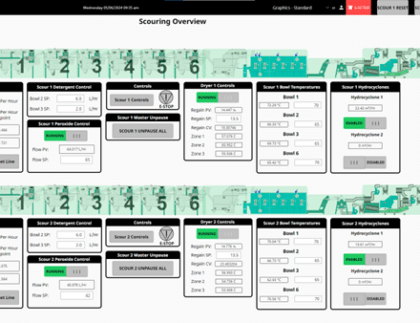

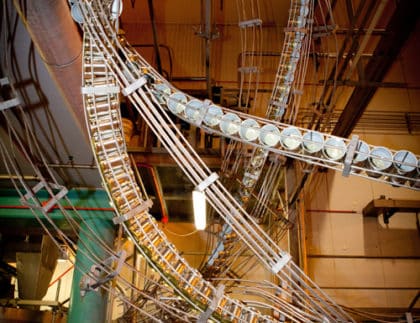

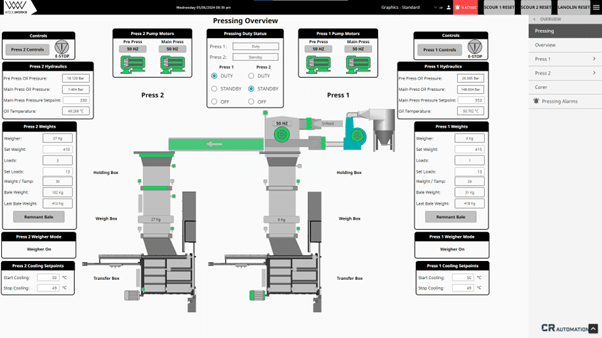

Due to the unavailability of documentation, functional descriptions for the plants systems were created based on what outdated software was still available. All stand-alone machines were incorporated into a new plantwide control system, implemented using seven Rockwell GuardLogix PLCs. The site’s updated control system also utilized over 30 point IO racks and had over 200 Schneider Altivar drives on the network. This system involved many automation aspects such as process control, burner control, hydraulics control, product weight sampling, historical data logging and trending, sitewide alarming and a significant upgrade to the plant’s safety system.

The entire plant’s control system is also now integrated into a modern SCADA system, built using Inductive Automation’s Ignition platform. Operator interfaces to access the SCADA system include monitor screens, touch screen displays and tablets for portability around the plant.

The results

WoolWorks’ Awatoto plant is now back in operation, with the ability to process wool at a greater rate than prior to the cyclone. The SCADA system provides operators with greater control of their plant and a significant increase in operator visibility. Operators are now able to access fault information more readily, as well as monitor production rates across the plant and manage the rates of their areas appropriately.