Process automation solutions for a colossal upgrade!

Our Client

Kraft Heinz's Hydro

Project Scope

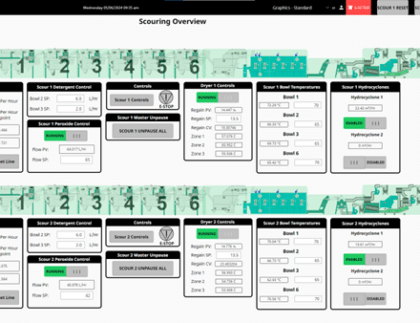

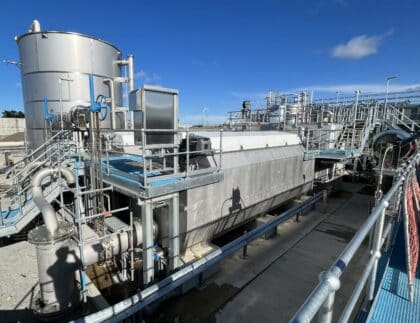

At the heart of Kraft Heinz’s central processing facility is a hydrostatic cooker capable of processing and cooking 60,000 cans of food at any one time in a continuous process. It is an integral part of their business and a potential breakdown presented a significant financial risk.

The existing control system had limited PLC hardware support. We were brought in for a full turnkey process automation solution, including an electrical and control system upgrade.

The CR Automation Solution

As the cooker is such an important part of Kraft Heinz's operation, we had to complete the work within a very tight time frame. We conducted an extensive design phase, completing a comprehensive electrical design, functional description, schematics, safety upgrade, PLC program and a new SCADA application.

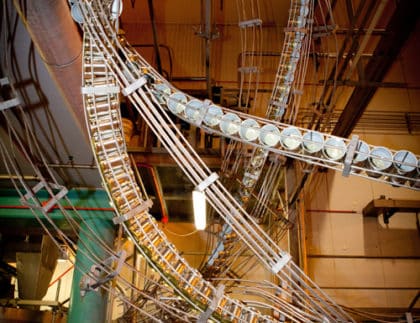

The results

The upgrade was delivered on budget and on time. We provided a more user friendly interface, and product tracking in the conveyor to assist with production logistics. This project demonstrated Kraft Heinz's confidence in us to manage a risky process on a large scale.