Packhouse equipment that sends pests packing

Our Client

Mr Apple (Longlands, Hawke’s Bay)

Project Scope

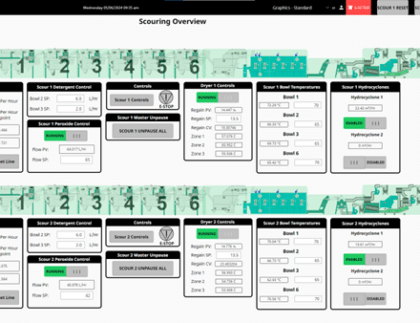

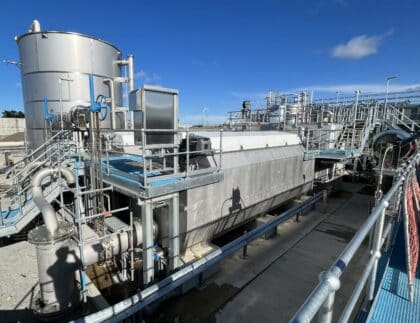

Mr Apple is one of the largest growers of apples in Hawke’s Bay. Their packhouse equipment at their Longlands facility was old and outdated. They were having downtime and reliability issues, which is the last problem a packhouse operation needs when fruit arrives. Most importantly, the packhouse equipment wasn’t removing the required volume of bugs which has a direct impact on sales.

The CR Automation Solution

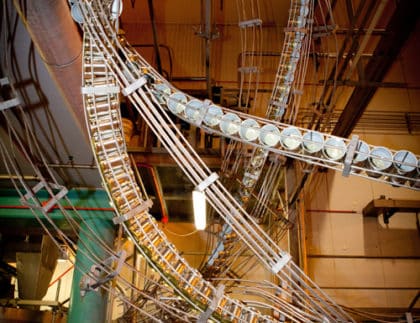

Starting with our standardised design, we adapted an infeed, washing and handling system to suit the space available at the packhouse and meet the washing requirements. We designed and manufactured the new packhouse equipment according to industry best practice and installed it in the off season so there was minimal interruption to their normal operations. The system was tested with cool store stock to ensure it was 100% ready to go for the next harvest.

The results

Mr Apple now have a highly automated system that provides friendly usage for workers on site. The quality of handling and washing of apples with the new packhouse equipment has given Mr Apple access to high value, pest sensitive markets. They’re getting more money for product, with much less damage.