Industrial automation and control where safety is paramount

Our Client

Nature's Flame

Project Scope

We successfully won the tender for the industrial automation and control of a green field site for Solid Energy working with Transfield Worley.

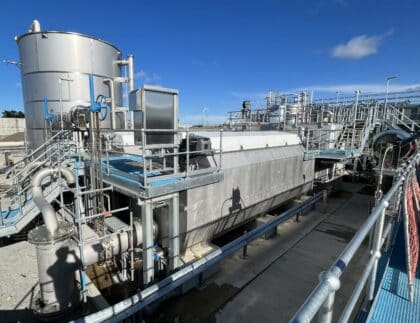

The Nature’s Flame facility would manufacture wood pellets for fires and boilers in New Zealand and the export market in Europe.

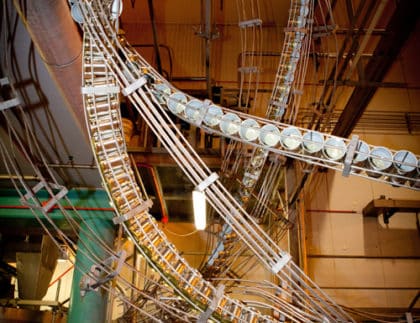

The production process included trucking in sawdust and converting it into pellets. Our challenge was to interface with other software and integrate third party machine controllers.

The explosive nature of sawdust added a layer of complexity to the automation process, where the control software had to account for the safety of workers and the facility as a whole.

The CR Automation Solution

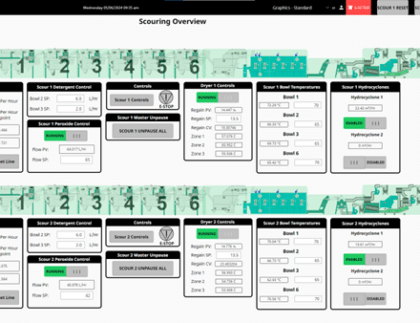

We used the functional descriptions provided by Transfield Worley to write software to control the transportation of the raw dust from storage bins onto a drying belt five metres wide and 70 metres long. The dried dust is deposited into a hammer mill which breaks the product into smaller particles before moving on to a dry storage area.

We then developed the software to transport the dry dust to the presses, the finished pellets to a storage area, and finally to load them onto trucks. Every machine and process is linked with an overall site SCADA solution. The plant operators also have portable tablets to control processes in a mobile capacity.

The safety software was written in a SICK PLC which monitors for failures in the safety system, anticipating problems before they occur, and shutting those processes down.

The plant is producing to expected capacity and Solid Energy are now reaching new export markets.

The results

After extensive product commissioning the plant was handed over to Natures Flame to produce the pellets for their world wide customer base. With a single operator on shift using the SCADA application on the remote tablets enable him to always be intouch with the process.