Case Study – A complete machine safety solution for Eastland Port's debarker

Our Client - Eastland Port

Located right in the heart of Gisborne city, Eastland Port is New Zealand’s most easterly commercial shipping port. Eastland Debarking has gone from strength to strength and now handles most of the quality logs harvested on the East Coast.

Project Scope

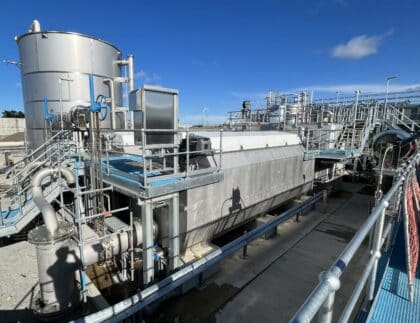

Eastland Port’s debarking machines are designed to completely remove bark from the logs, which means they are insect free and able to be loaded as deck cargo without harsh chemicals. Debarking is much better for the environment and most of the bark is re-used as quality garden mulch. Eastland Port wanted to ensure the debarking machine was compliant with AS/NZS4024 machine safety standards.

The CR Automation Solution

CR Automation performed a machine safety risk assessment using our inhouse developed methodology. This gave Eastland Port a risk assessment of the machine and identified risk reduction measures.

CR Automation provided a mechanical, electrical and automation design for Eastland Port to competitively tender the engineering improvements.

CR Automation tendered for this work and successfully won the electrical and automation component.

This consisted of,

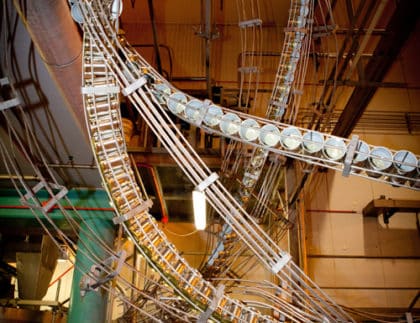

- An upgrade of the Motor Control Centre (MCC)

- An upgrade of the legacy Rockwell SLC 5/03 PLC to a 5069-L33ERS2 Compact GuardLogix.

- The implementation of a new safety system including Emergency stops, interlocked gate access controls, pneumatic and hydraulic safe isolations.

- New variable speed drives to integrate with the safety system using Safe Torque Off (STO).

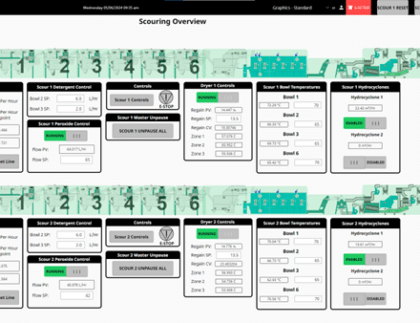

- The installation of an Ignition Edge Human Machine Interface

- Safety verification and validation of the completed project

The results

Eastland port now have a fully machine safety compliant Debarker, protecting the operators who interact with this critical piece of equipment. A secondary benefit, thanks to utilising the latest safety technology, throughput of logs has also increased.

Eastland Port Operations Projects Manager, Mark Richards, comments “CR Automation where able to take care of the whole safety upgrade project, from the initial risk assessment, safety design, implementation and validation. The increased log throughput has been a significant improvement to the business as well as knowing our people are safe when working with this machine”.