Customisable modular system for removing pests and debris from produce

Contact us to discover how automation solutions can transform your business.

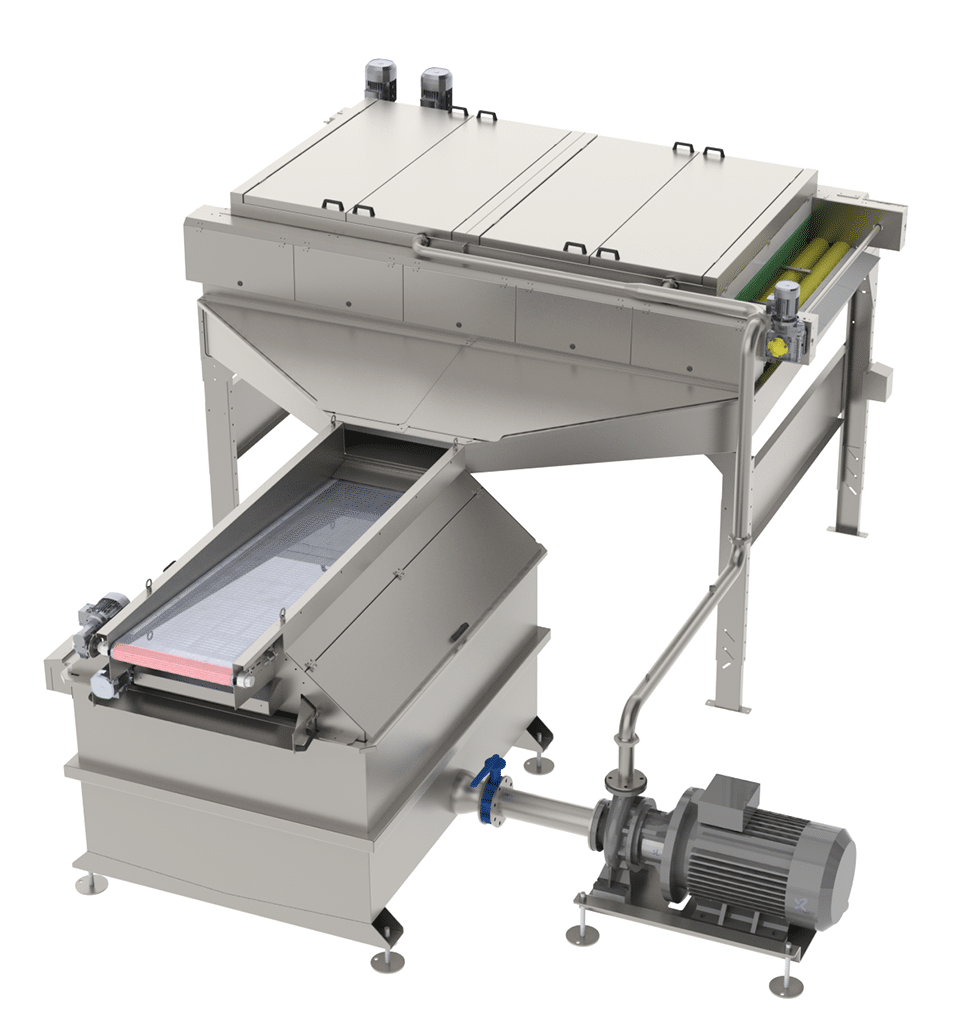

System Components

- Flat bed brush unit

- Multistage high volume filtration system

- Manifold and pump system delivering 100 PSI at the nozzle

- Touch screen control and advanced PLC communications

Key Features

- Multistage filtration up to 150m3 per hour of water down to 200 microns reducing water consumption and protecting pumps and nozzles from blockage.

- Touch screen control and advanced PLC communications ensuring seamless line integration and simple operation.

- Customizable alternating brush speeds provide a variable scrub action to take care of delicate skin produce while still providing the tools required to eliminate hard to remove contaminants.

- Intelligent progressor system, with no drive components in the fruit area giving superior safety, food hygiene, cleanability and longer machine life.

- Triple sealed drive cavity separating the wet wash area from the dry mechanical drive area.

- Stainless steel construction.

- Quick release square drive brush system.

- Quick release spray nozzles.

- AS/NZS 4024 Machine Safety Compliant.

- Meets MPI Requirements for exporting apples out of NZ.

- Sensor controlled pump speed to ensure compliant pressure is always maintained.

- Nozzle wear routines compensate for wear extending the usable life of your nozzles.

- Self-diagnosing algorithms will inform the operator if the spray nozzles require maintenance ensuring export compliance.